HOW TO CHOOSE BACKCOUNTRY SKIS

Pick the best planks for your terrain of choice.

Add $99.00 more to quality for free Shipping!

$0.00 USD

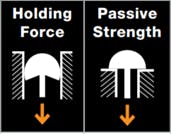

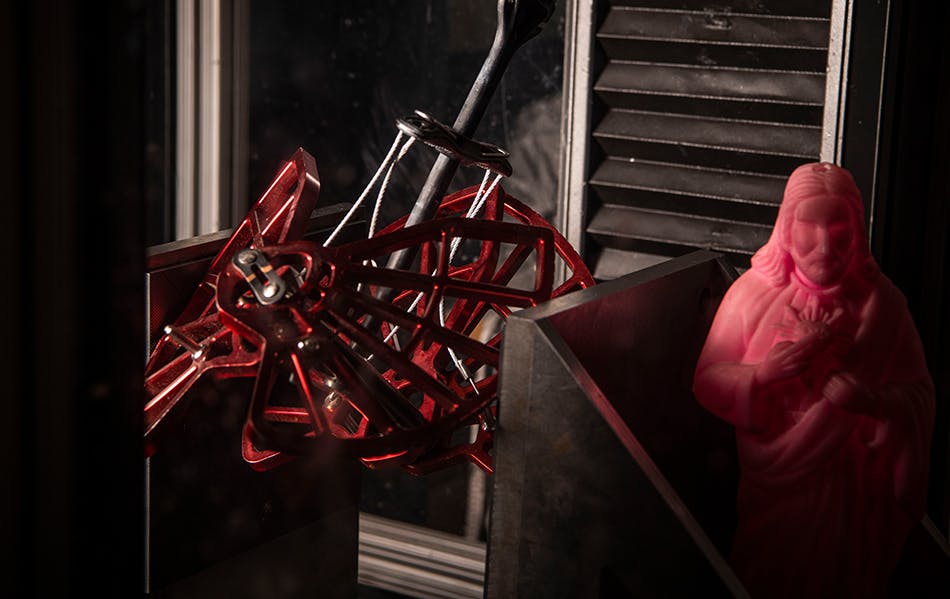

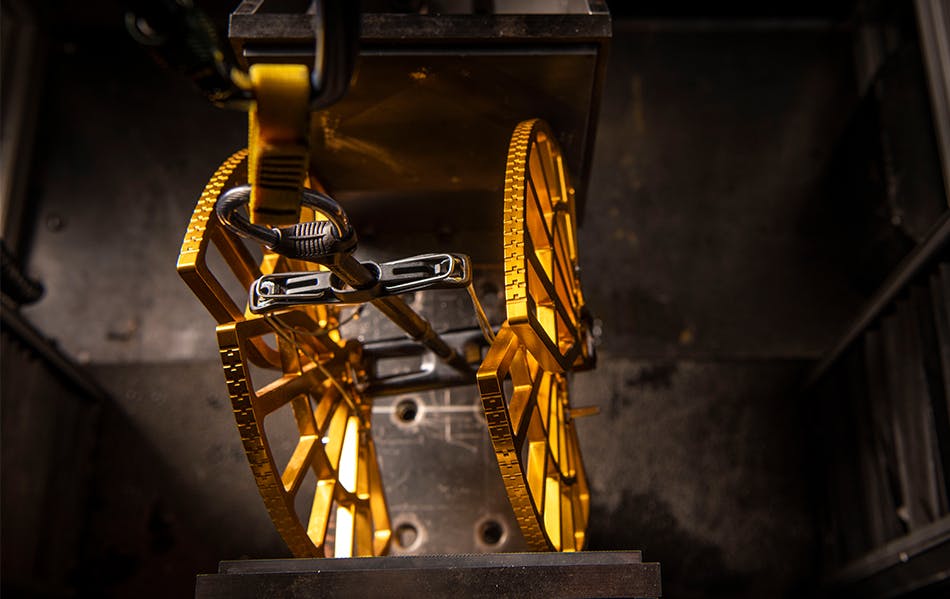

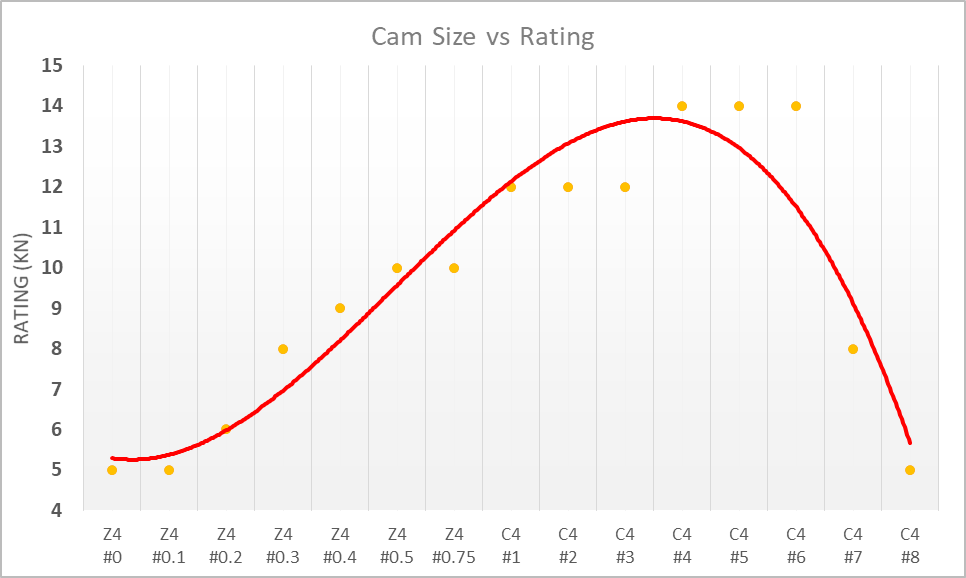

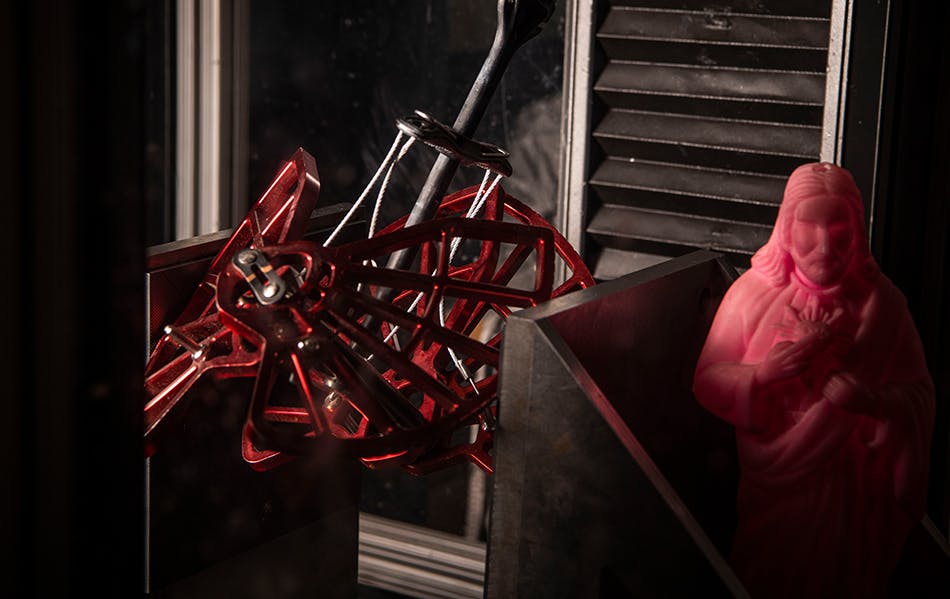

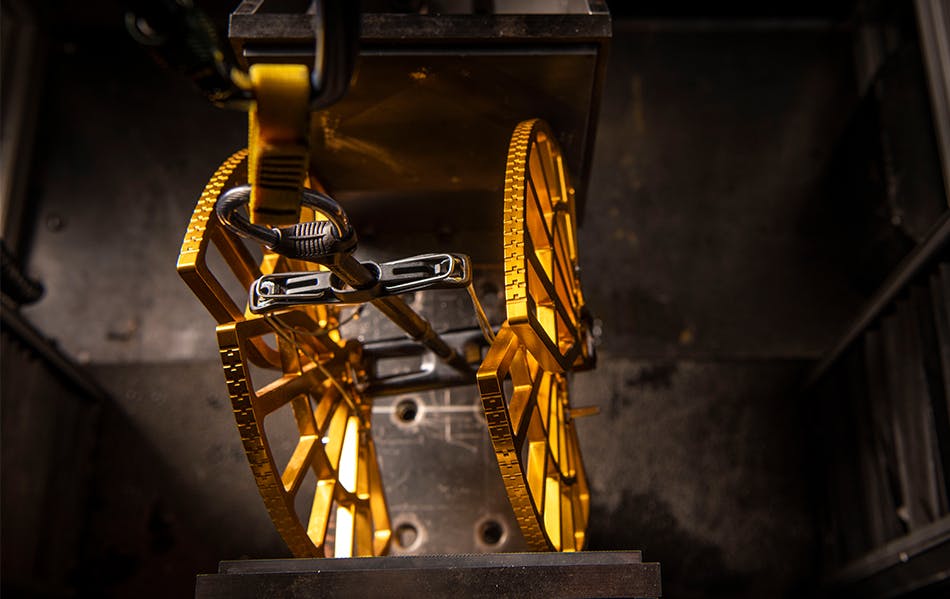

The new C4 #7 & #8 Camalots are massive cams, some of the biggest out there. They make the C4 #5 look like a hand-sized piece! These big beasts are made for protecting grueling desert off-widths, wide pitches mid-way up El Cap and everything else maw-gapingly wide. This year we released our smallest and biggest cams ever made—the micro size Z4 #0 and now these big boys. At first glance you might not imagine that these sizes have anything in common but that isn’t necessarily true. Size usually plays into the perception of the strength of a cam. It’s much more confidence inspiring to fall or hang on a hand-size cam than a tips-crack piece. This is true for the majority of sizes up to a critical point, which is reached with these extra-large pieces. In this QC lab we will explore and compare the performance similarities of the C4 #7 and #8 to the Z4 #0, as well as show why these monster-sized cams are rated closer to a micro cam rating than you may think.

The new C4 #7 & #8 Camalots are massive cams, some of the biggest out there. They make the C4 #5 look like a hand-sized piece! These big beasts are made for protecting grueling desert off-widths, wide pitches mid-way up El Cap and everything else maw-gapingly wide. This year we released our smallest and biggest cams ever made—the micro size Z4 #0 and now these big boys. At first glance you might not imagine that these sizes have anything in common but that isn’t necessarily true. Size usually plays into the perception of the strength of a cam. It’s much more confidence inspiring to fall or hang on a hand-size cam than a tips-crack piece. This is true for the majority of sizes up to a critical point, which is reached with these extra-large pieces. In this QC lab we will explore and compare the performance similarities of the C4 #7 and #8 to the Z4 #0, as well as show why these monster-sized cams are rated closer to a micro cam rating than you may think.

Before diving into the test results, it is important to understand a few of the key definitions that will be used throughout:

Refers to the load at which there is total failure of the cam, most often this is shown in kilonewtons (1kN is about 225lbf). These loads are determined by a slow loading of the cam at various predetermined sized “cracks” based on the expansion range of the cam. For a cam, or in the official lingo, friction device, to meet CE requirements, the minimum ultimate strength must be 5kN or 1124lbf.

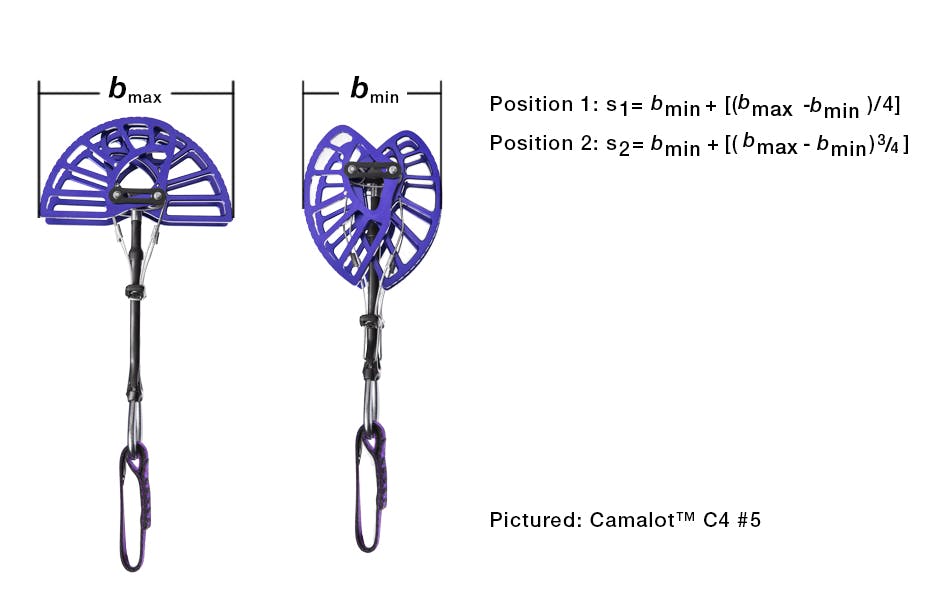

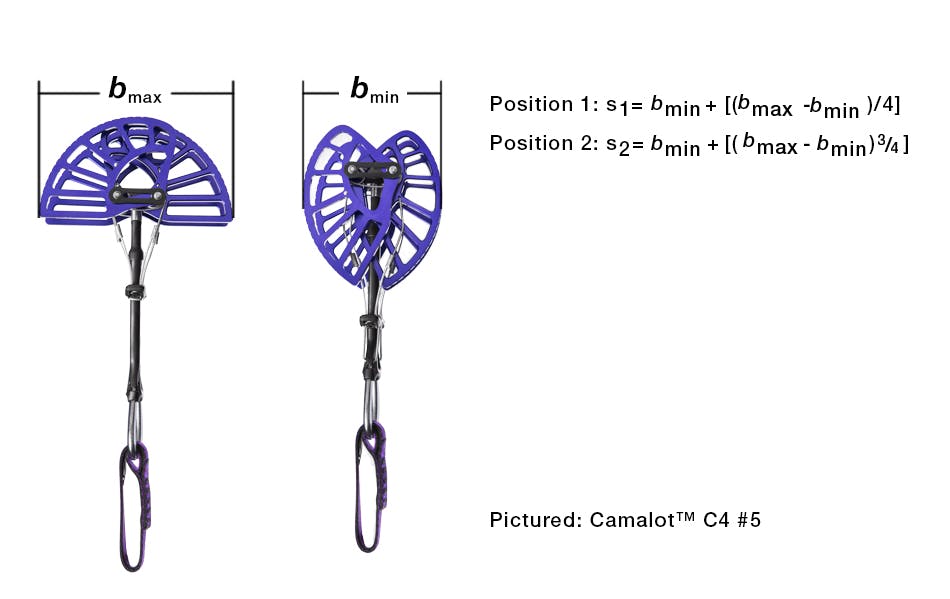

For all personal protective equipment (PPE) to be sold in Europe it must be CE certified. Each category of equipment has its own specific set of requirements outlined in the EN standard: for cams this standard is EN12276 - Frictional Anchors. There are many requirements in the standard including ones for markings, instructions, use of materials etc. but the main one we will be looking at here is the ultimate or breaking strength. There are two main destructive tests that a cam must pass to be certified: loaded at 25% retracted; and loaded at 75% retracted. These represent a less than ideal, sketchy placement (25% retracted) and a stronger, more preferred placement of 75% retracted. The following formulas are used to find the appropriate placement widths with Bmin referring to the retracted width and Bmax being the fully non-retracted dimensions of the cam.

Figure 1: CE test spacing for 25% and 75%

Note: If a cam has a range of 5mm or less the CE standard requires it to be tested at 50% retraction vs the 25% or 75%, the Z4 #0 meets this requirement.

Figure 2: CE test spacing if total range of cam is less than 5mm

– To show the difference in strength between 25% and 75% the % strength reduction will be determined using the following formula.

Figure 3: Formula for % Strength Reduction

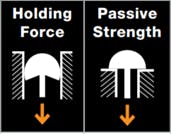

– The marked rating is the load which the manufacturer claims the product can consistently meet under test conditons. The minimum allowed rating outlined in the CE standard is 5kN (1124lbf). When looking at the markings on the sling of a cam there may be two ratings listed; one for active strength (the normal way that a cam is placed) and one for passive (referring to the cam being used as a nut/stopper). For Black Diamond cams, only the dual axle versions are rated for passive strength.

Figure 4: Markings that display ratings for holding force and passive strength found on the cam sling.

Now this doesn’t necessarily mean that if a cam is rated to 8kN it will fail at 8kN. Ratings are determined and calculated using what is known as a three-sigma calculation. By testing a statistically relevant population and determining the mean (µ) and standard deviation (σ) the lower three sigma bound can be found. From this it can be said that 99.7% of failures will be at a load above the lower bound. This is the starting point for determining the published rating. After taking into consideration the various use cases of the product the rating could be lowered further.

Lower Bound = µ - 3 * σ

Lower 3 sigma calculation used when determining ratings

Figure 5: Trend of published CE ratings of C4’s & Z4’s as cam size increases

For the purposes of this article certain cam sizes will be labeled small, medium and large, the breakdown of specific sizes is listed below.

No matter what size cam you’re placing, you should always aim to make the best placement possible, however, this isn’t always possible. There are variations in the rock, you have a limited number of cams to use along the pitch and sometimes you would just plain rather have something instead of nothing. But how much do those funky placements affect the strength of the cams at either end of the spectrum?

As with all QC Labs it is important to remember that we are dealing with a small sample size and testing in pretty-much ideal conditions: the test setup is accurately measured and tested with steel file plates to ensure as little variation as possible.

To keep it simple, we narrowed it down and decided to perform two different sets of tests:

- Following the CE standard - the Z4 #0, C4 #7 & #8 as well as variety of mid-range cams.

- A nonstandard asymmetrical test of only the larger C4’s.

- To show the realities and limitations of larger cam placements.

#1 Camalot – rating 14kN – tested at 50% retracted - Broke at 15.5kN

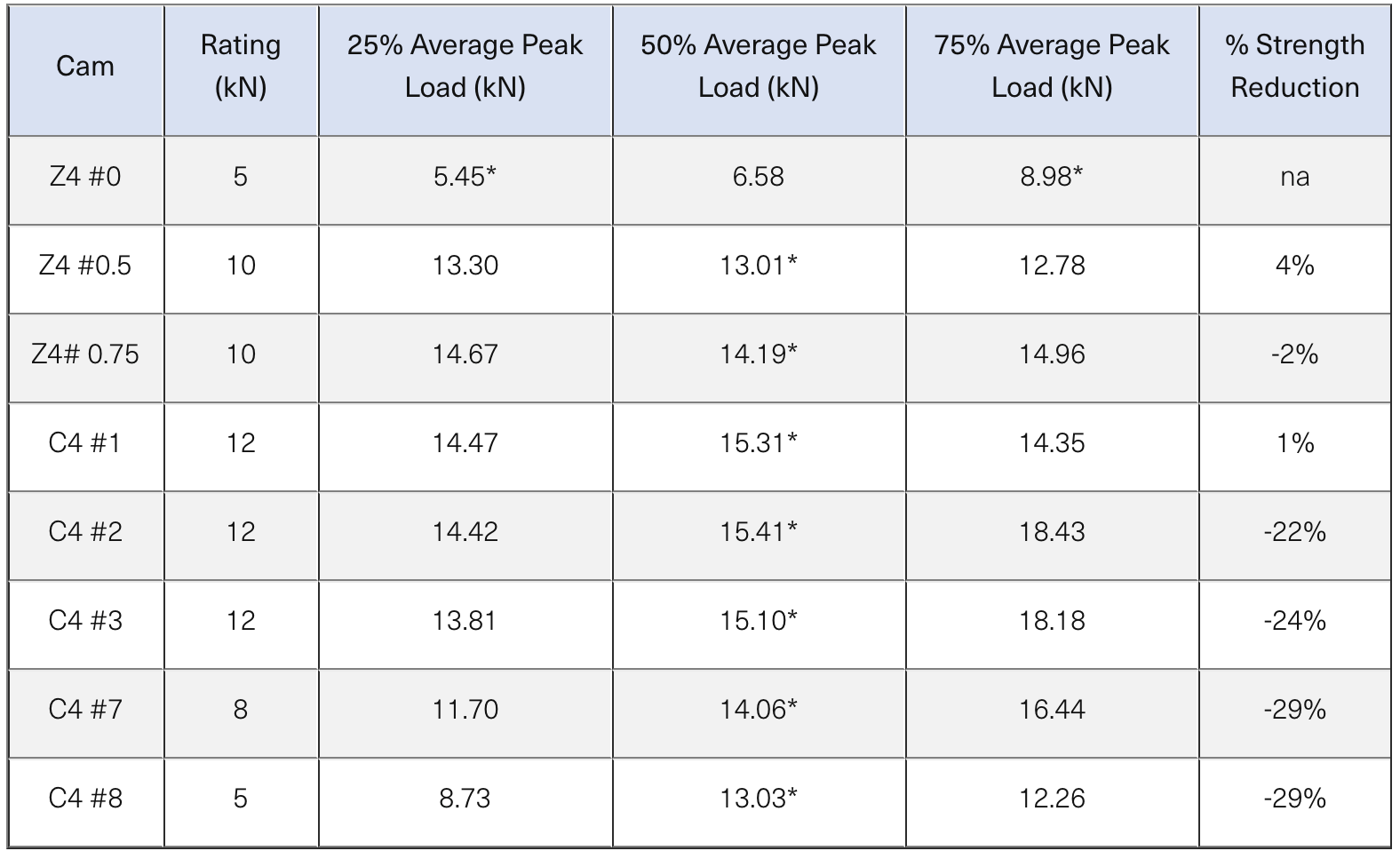

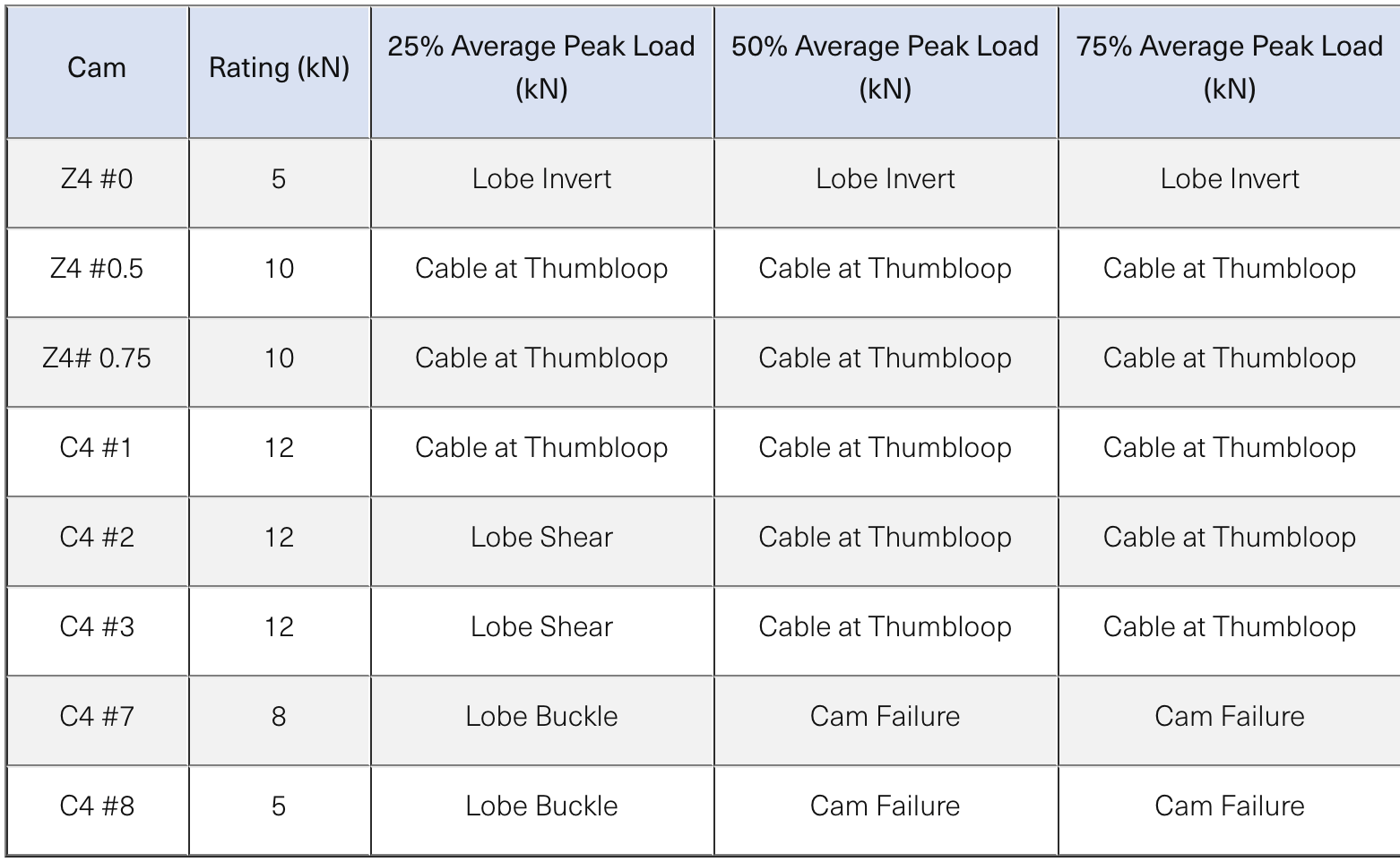

The following table shows the results when tested to the CE standard test set-up (for simplicity not every size of cam is shown):

Table 1: Testing summary for various Z4 and C4 cam sizes. – tested to standard CE testing protocol

*Not required by the CE standard testing but added to table for completeness

When looking at the results in table 1, there are several key takeaways:

The way in which cams fail can be different:

Placing a large cam with minimal retraction can significantly reduce the strength of the unit due to the tendency for the lobes to buckle. Placing a micro cam with minimal retraction can also significantly reduce the strength of the unit due to the tendency for the lobes to invert. While the failure mode is very different for both sizes of cams, their sensitivity to “tipped out” placements remains nearly the same.

As a side note it is worth mentioning that as the cam gets closer to 100% retraction the stronger it will be. It is commonly overheard that a cam is weaker when placed at full retraction. Some call this condition being “over-cammed.” This is not true. The closer that a cam is placed to 100% retraction, the stronger it is. The downside to placing a cam at full retraction is that it might be challenging if not impossible to remove without damaging the cam or rock.

During the development of a new product here at BD, there are many tests in addition to the CE standard tests that are created and completed in order to validate a product. These tests are performed to better understand the effects of potential misuse scenarios that may occur in the field. One such test involves holding the cam at an angle that is off axis from the direction of pull to see what happens. All the previous testing in this article has been done under ideal conditions and placements.

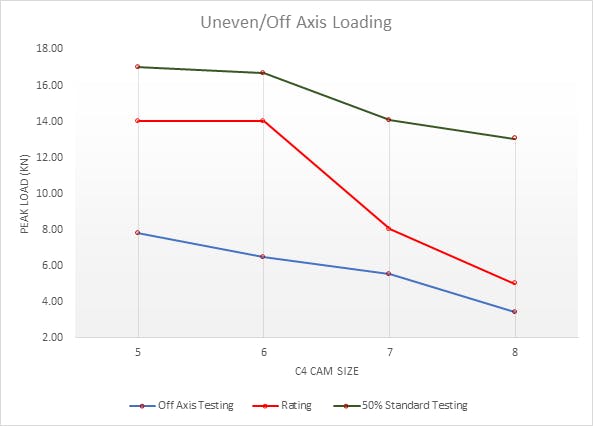

So, what happens to the strength of large cams when they are placed off-axis from the direction of pull?

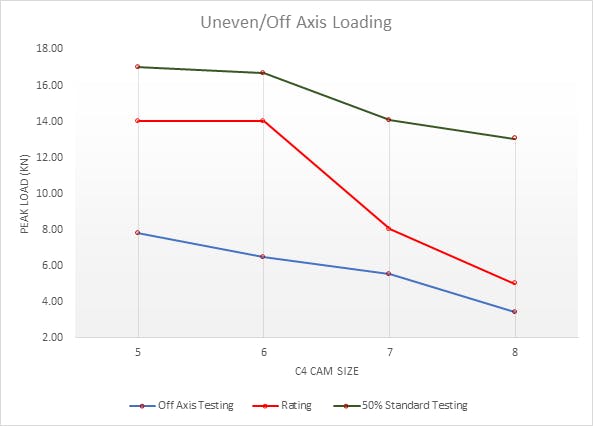

This second round of testing was done on the larger size C4’s (#5, #6, #7, #8) and placed at roughly 30 degrees off from vertical at a spacing of 50% retraction with the retraction of the lobes uneven. In many cases the cam will attempt to orient toward the direction of pull but in the case of this test the cam was held out of line to represent the worst-case scenario.

From earlier testing it was already determined that as the size gets larger the instability increases. The following points are key components to the large C4’s decreased performance during uneven loading:

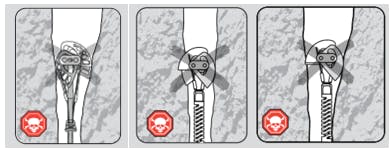

Large cams are more vulnerable to strength reductions than smaller cams when placed off axis from the direction of pull. It is essential that large cams are placed such that they are oriented in the direction of loading, with the individual cam lobes retracted as evenly as possible, and retracted as much as possible.

At BD, we consider more than just the standard CE requirements when assigning a rating to the cam size. The results of our internal tests are also heavily considered.

When looking at the testing results above, the loads are well above the 5kN rating (for the Z4 #0 & C4 #8) and the 8kN rating (for the C4 #7). However, because of the known limitations and sensitivity to placements, a conservative rating was chosen to convey the need for the user to strive for a more optimum placement when possible.

It is very unlikely that every placement in the field is going to be perfect, and for some sizes that is more acceptable than for other sizes. While every piece should be placed with care, extra caution should be used for cam sizes at the far ends of the spectrum:

Sufficient cam retraction and symmetrical loading are the keys to a good placement.

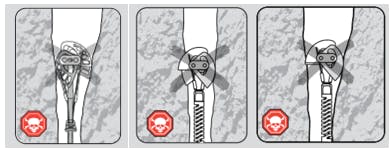

Figure 7: Our cam instructions highlight a few suspect placement scenarios to be aware of.

Even though the size of the large cams can give the appearance of a strong, secure anchor, their ultimate strength performance is similar to a micro cam and needs to be treated as such before deciding to take the big ride out of some gnarly off-width.

Be Safe out there,

HG

Inspired by climbing, created by hand, our Spring 2026 prints tell a deeper story.

Basic field maintenance and repair tips for your climbing skins from our Reroute team.

Watch Connor take down another classic testpiece on the Empath cliff in Kirkwood, California.

Follow BD Athlete Yannick Glatthard deep into the Swiss Alps as he shares his home...

Follow BD Athlete Yannick Glatthard deep into the Swiss Alps as he shares his home mountains with close friends.

Follow Dorian Densmore and Mya Akins for another winter season of steep Alaskan spines, backyard...

Follow Dorian Densmore and Mya Akins for another winter season of steep Alaskan spines, backyard couloirs, and deep adventures in the mountains.

Watch BD Athlete Alex Honnold throw down on some hard trad high above Tahoe.